Precision CNC Machining Zinc Alloy/Zamak5 Die Casting LED Lighting Heatsink Housing Part

Description

Basic Info.

| Model NO. | DC02 |

| Machining | CNC,Machining Center,Lathe,Milling,Honing |

| Material | Aluminium Alloy, Zinc Alloy, Brass, Mg Alloy |

| Surface Preparation | Blasing,Polishing,Powder Coating,Paint,etc |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 2 |

| Certification | CE, ISO 9001:2008, SGS |

| Casting Tolerance | CT4-CT6 |

| Inspection | CMM, Normal Gague, Part Special Customized Gague |

| Part Weight | 10g-100kgs |

| MOQ | 1PC |

| Machining Tolerance | 0.001 |

| Drawing Format | 2D:Pdf, Dwg, 3D: Igs,STP, |

| Quality Control | Flow Chart, Control Plan, Pfema, Cpk |

| Surface | Polishing,Shot Blasting,Powder Coating, Painting,E |

| Process | Mould Manufacturing, Die Casting, CNC Machining |

| Transport Package | Pallets, Paper Box, Carton, Crate, |

| Specification | as customer request |

| Trademark | as customer request |

| Origin | China |

| HS Code | 8302410000 |

| Production Capacity | 600tons/Month |

Packaging & Delivery

Package Size 30.00cm * 30.00cm * 46.00cm Package Gross Weight 2.600kgProduct Description

Product DescriptionQingdao ACES is a professional OEM manufacturer with extensive experience for casting,machining and surface treatment, especially for high strict surface treatment request.

| Item | Specification |

| Material | ADC10,ADC12,ADC14,A356,A360,A380,ZAMAK3#,ZAMAK5#,ZAMAK8#,Magnesium alloy AZ91D, AM60B,Brass,Copper and others as customer request |

| Process | gravity casting, sand casting,die casting. |

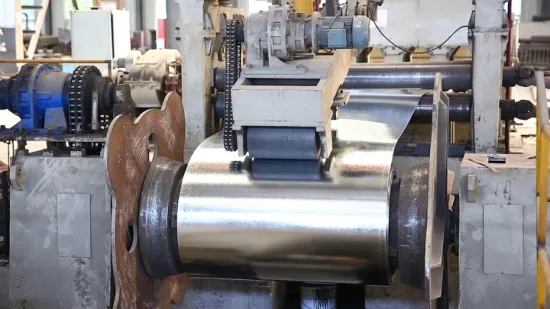

| Die Casting Machine | 180tons to 900tons and 1200tons |

| Surface treatment | polished,wet painting,powder coating,e-coating,electro-plating;PVDF coating;anodizing,chemical blacken; |

| Machining process | turning,milling,drilling,boring,grinding,reaming,honing etc. |

| Inpection | CMM inspection, gauge inspection,hydro or air pressure test, NDT test;We also can customize the inspection tools acoording to the part demands. |

| Mould life | 200000pcs |

Qingdao ACES is an OEM manufacturer, mainly for casting parts, CNC machining parts and sheet metal stamping parts. We have wide experience in producing and exporting metal parts, not only for OEM parts but also have the professional team for ODM.

ACES will design the suitable package for each part during sample development according to the part structure, qty per lot and customers requirement.

Q1: How to get the quotation?

A1: For quotation we need the customer to offer the 2D and 3D drawings, usage information, material request, surface treatment and other technicial which need to pay attention and other information which will affect the quotation.

A2: Normally it will need 1 to 5 days.

Q3: Can you produce the parts according to the samples?

A3: Yes, we have the reverse engineering capability.

Prev: OEM Customzied Bespoke Housing Suit Aluminum Parts for LED Strip Lighting

Next: Complete 8kw 10kw 12kw Home Use Hybrid Grid Tie Solar Power Generator Kits for Home

Our Contact